|

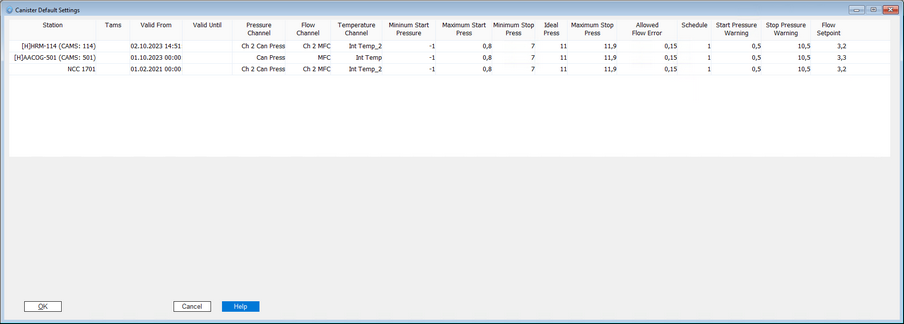

Canister Settings |

Scroll

| |

|

You can configure canister settings for your test gas samplers in the stations. After the canister run (normally 24 hours) you can evaluate the different parameters of the test run by the settings defined here. Use these settings to judge how the filling process worked.

▪Start Canister Settings from the Import > Interface main menu.

▪Add a new set of settings for your canisters with the context menu item Add.

▪Specify the following settings:

Element |

Description |

|---|---|

Station |

Select the station where the canister is installed for which you define settings here. |

Tams |

Any arbitrary string for the current settings. |

Valid From |

Specify the start of validity for the canister settings. |

Valid Until |

Specify the end of validity for the canister settings. If no end date is specified, the canister run settings are valid indefinitely. |

Pressure Channel |

Specify the channel that provides the pressure data for the canister run. The values from this channel can be used to monitor the correctness of the gas filling during the canister run. |

Flow Channel |

Specify the channel that provides the flow values to be used to monitor the correctness of the gas filling during the canister run. |

Temperature Channel |

Specify the channel that provides canister temperature data to evaluate the correctness of the canister run. |

Minimum Start Pressure |

Specify the minimum pressure at the start of the canister run. The pressure on start of the canister run must lie between the minimum and maximum start pressure. Valid for all pressure values defined here: If exceeded or underrun, the canister run is judged as invalid. |

Maximum Start Pressure |

Specify the maximum allowed pressure at the start of the canister run. |

Minimum Stop Pressure |

Specify the minimum allowed pressure at the end of the canister run. |

Ideal Pressure |

Specify the pressure value inside the canister that is regarded as optimum. |

Maximum Stop Pressure |

Specify the maximum allowed pressure at the end of the canister run. |

Allowed Flow Error |

Specify the maximum allowed error for flow measurement during canister run. |

Schedule |

Select a canister sampling schedule. Normally, the canister runs every 3 or 6 days. Note: The schedules are managed in the SYS_REP module. |

Start Pressure Warning |

Specify the pressure value where a warning is provided at the start of the canister run. |

Stop Pressure Warning |

Specify the pressure value where a warning is provided at the end of the canister run. |

Flow Setpoint |

Specify the set point (target value) for the flow. |

See canister functions in general DMO documentation.